What is Stainless Steel Woven Wire Mesh and its Uses?

stainless steel woven wire mesh is a versatile material widely used in various industries. According to Dr. Emily Carter, an expert in industrial materials, "The durability and flexibility of stainless steel woven wire mesh make it ideal for numerous applications." This mesh is not just about functionality; it's about enhancing safety and efficiency.

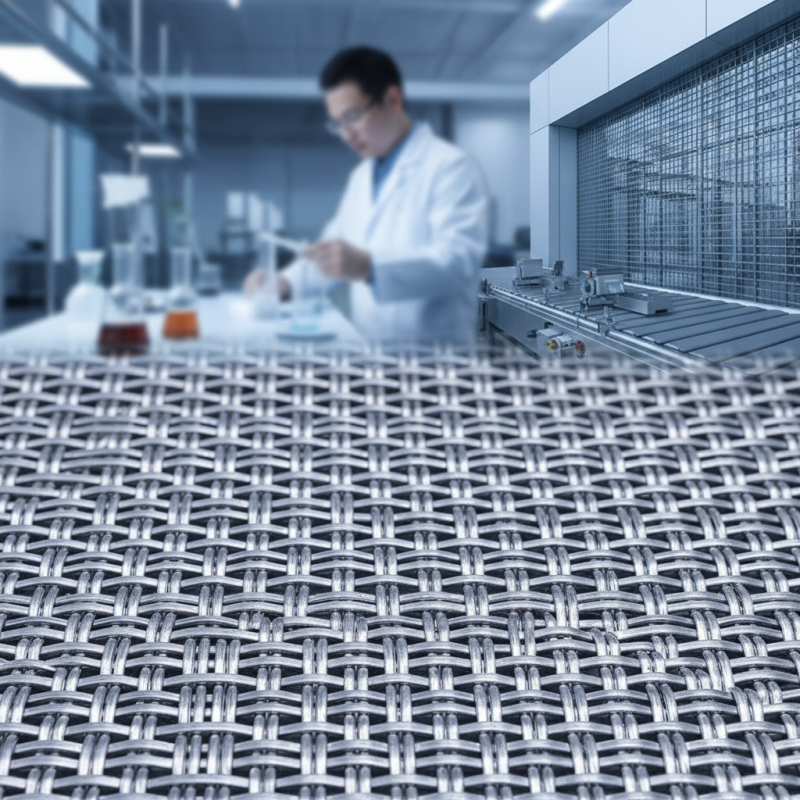

The weaving process involves interlacing stainless steel wires, creating a strong structure. It can withstand harsh environments and provides excellent corrosion resistance. For example, it is used in filtration systems, architectural projects, and even food processing. The beauty of stainless steel woven wire mesh lies in its adaptability.

Despite its many advantages, some challenges exist. Sizing and material variation can impact performance. Proper selection is crucial for achieving desired results. Therefore, understanding the nuances of stainless steel woven wire mesh is essential for those working with it. This material is powerful, yet it requires careful consideration.

What is Stainless Steel Woven Wire Mesh?

Stainless steel woven wire mesh is a versatile material used in various applications. It is crafted by weaving stainless steel wires together, creating a strong, durable fabric. This type of mesh is known for its resistance to corrosion and high temperatures. Commonly, it is used in filters, guards, and even decorative purposes. Its strength and flexibility make it ideal for different industries.

The manufacturing process involves precise weaving techniques. Each wire is tightly interlaced, ensuring robustness. The mesh can be customized in terms of thickness and opening sizes. Many industries, from construction to food processing, rely on stainless steel woven wire mesh. However, it is crucial to consider the specific requirements of each application. Not all meshes suit every environment.

Some may overlook the importance of selection. Mesh that is too fine may clog easily, while a coarser mesh might not filter effectively. Careful consideration of the intended use is essential. Misapplication can lead to inefficiency. Choosing the right type takes time and research, reflecting the complexity of this simple yet vital material.

History and Development of Stainless Steel Woven Wire Mesh

The history of stainless steel woven wire mesh traces back to the early 20th century. The introduction of stainless steel significantly changed the landscape of materials used in various industries. Before stainless steel, metal mesh products faced issues like rust and corrosion. The advent of stainless steel, known for its durability and resistance, revolutionized mesh applications.

Over time, stainless steel woven wire mesh evolved through innovative designs and improved manufacturing techniques. The mesh became widely used in architecture for facades and interior designs. Filtration industries also embraced it due to its effectiveness in separating particles. This versatility highlights the mesh's importance in modern applications, yet challenges remain in balancing strength with weight.

Tips: When selecting stainless steel woven wire mesh, consider the specific requirements of your project. Also, always evaluate the mesh for its intended environment. Not all meshes perform equally well in every situation. Testing a sample can sometimes reveal unexpected weaknesses.

Key Characteristics and Benefits of Stainless Steel Woven Wire Mesh

Stainless steel woven wire mesh is a versatile material. It is made by weaving stainless steel wires together. This creates a strong, durable structure ideal for various applications. Industries often choose it for its strength and resistance to corrosion. It can withstand harsh environments, making it suitable for outdoor use.

One key characteristic of stainless steel woven wire mesh is its flexibility. It is available in different mesh sizes and wire diameters. This allows for customization according to specific needs. The tight weaves can filter small particles effectively. On the other hand, looser weaves allow for greater airflow.

Tips:

- When choosing the mesh, consider the application.

- Think about the environment where it will be used.

- If exposure to chemicals is likely, opt for higher grades of stainless steel.

- Also, ensure proper installation for optimal performance. This is crucial to avoid any potential issues in the future.

Overall, the benefits of stainless steel woven wire mesh are plentiful. It offers excellent strength, durability, and resistance to rust. However, ensure regular maintenance, as buildup can occur over time. Choosing the right type of mesh requires careful thought. Be mindful of your specific needs and conditions.

Common Applications of Stainless Steel Woven Wire Mesh

Stainless steel woven wire mesh is known for its strength and versatility. This mesh is made of interwoven strands of stainless steel. It comes in various weaves and sizes, making it suitable for a range of applications. Its durability against corrosion is one of its key attributes.

In industrial settings, stainless steel woven wire mesh is widely used for filtering and sieving. It's common in food processing and pharmaceuticals. The mesh can control the size of particles effectively. In construction, it serves as reinforcement for concrete or as a partition. It provides structural support while maintaining airflow.

Some less common uses include art and design projects. Artists repurpose the mesh for sculptures or decorative elements. However, it can be challenging to work with due to its rigidity. On site, installers might find the exact fit difficult. The mesh often requires precise measurements, which can be a hassle. These factors make it essential to plan carefully and think through the design before starting.

Maintenance and Care for Stainless Steel Woven Wire Mesh

Stainless steel woven wire mesh is durable and versatile. However, it requires proper maintenance to extend its life. Regular cleaning is essential. Use mild detergent and warm water, ensuring to remove any debris. Avoid abrasive cleaners, as they can scratch the surface.

Inspect the mesh periodically for signs of wear. Look for any bent wires or loose weaves. Addressing these issues early can prevent costly replacements. If rust appears, it’s crucial to act quickly. You can use a soft brush to remove light rust spots. For more severe cases, consider a specialized rust remover.

Stainless steel mesh can be affected by environmental conditions. High humidity can lead to corrosion, even in stainless steel. Using a protective coating can be beneficial. However, some coatings may wear out over time. It’s important to reapply them as needed. Regular maintenance, though sometimes overlooked, is key to longevity.