What is stainless steel wire mesh and its uses?

stainless steel wire mesh is a crucial component in various industries. Its durability and resistance to corrosion make it an ideal choice for filtration, separation, and reinforcement applications. According to a recent market report, the demand for stainless steel wire mesh is expected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This trend indicates a significant rise in its use across multiple sectors, including construction, food processing, and aerospace.

Industry expert Dr. Emily Johnson emphasizes the versatility of stainless steel wire mesh. She states, “This material is essential for both structural integrity and aesthetic appeal.” The wide-ranging applications highlight its importance. However, the manufacturing quality varies significantly. Not all products meet stringent industry standards, which can lead to performance issues.

As industries expand, the reliance on high-quality stainless steel wire mesh increases. The challenge lies in ensuring that manufacturers maintain high standards without compromising on cost. Continuous innovation in this field will be necessary to meet evolving market needs while addressing environmental and economic concerns. The future of stainless steel wire mesh will be shaped by these factors, making it a subject worthy of exploration.

Definition and Composition of Stainless Steel Wire Mesh

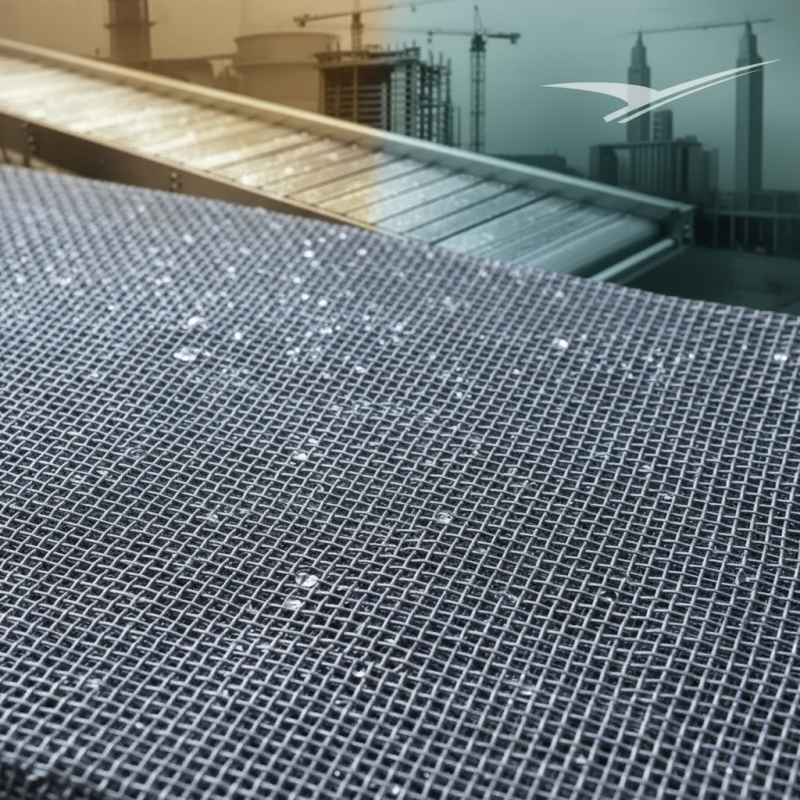

Stainless steel wire mesh is a versatile material made from alloy steel. It contains chromium, which provides excellent corrosion resistance. This mesh comes in various sizes and shapes, making it suitable for many applications. The fine wires can be woven together in different patterns, enhancing its strength and durability. Stainless steel is known for its aesthetic appeal as well, often maintaining a polished look in various environments.

When using stainless steel wire mesh, it's essential to consider the purpose. For filtering, a finer mesh is required. In architectural applications, aesthetics and strength both play a key role. Ensure the mesh’s specifications match your project needs.

Tips: Always check the mesh for uniformity. Uneven weaving can weaken its structure. Consider the environment where it will be used. Exposure to harsh conditions can affect performance. Make adjustments based on your observations. Reflecting on these factors can enhance your project's success.

Manufacturing Processes for Stainless Steel Wire Mesh

Stainless steel wire mesh is made through several key manufacturing processes. It starts with stainless steel rods, which are cut into precise lengths. These rods are then drawn through dies to create wires of desired thickness. This process is crucial. If the wire is too thick or too thin, it won't serve its purpose effectively.

Next, the wires are woven together. Different weaving patterns exist, such as plain or twill weaves. The choice often depends on the intended use of the mesh. Plain weave is common for filtration, while twill offers greater flexibility. Each pattern has its own advantages and disadvantages. Sometimes, the wrong choice can lead to inefficiencies in function.

After weaving, the stainless steel mesh undergoes finishing treatments. These treatments could include heat treatment or surface polishing. They enhance the mesh’s strength and resistance to corrosion. However, this step can vary. Some manufacturers might skip it, resulting in less durable products. Attention to detail is essential here. The quality of the final product relies on each step of the process, and missing one could compromise everything.

Common Applications of Stainless Steel Wire Mesh in Industry

Stainless steel wire mesh is widely used across various industries, primarily due to its corrosion resistance and durability. Its applications range from filtration to security. In the food and beverage sector, stainless steel mesh serves as a vital filtration material. According to industry reports, over 30% of the filtration market relies on stainless steel for its resilience and efficiency.

In construction, stainless steel wire mesh reinforces concrete structures, improving strength and longevity. Studies show that using stainless steel in building materials can increase lifespan by up to 50%. Additionally, it is used for safety barriers in commercial and industrial settings, enhancing security while allowing visibility.

Tips: Always consider the specific needs of your project. Selecting the right mesh size and wire diameter can significantly impact performance. Also, be aware that not all stainless steel mesh is created equal. Different grades have varying levels of corrosion resistance and strength. When in doubt, consult a professional to avoid costly mistakes.

Common Applications of Stainless Steel Wire Mesh in Industry

Key Properties of Stainless Steel Wire Mesh and Their Impact on Performance

Stainless steel wire mesh is a versatile material. Its properties make it suitable for various applications. The wire mesh consists of tightly woven stainless steel strands, ensuring durability and resistance to corrosion. The fine mesh design allows for airflow while keeping contaminants out.

A key property of stainless steel wire mesh is its strength. It can withstand heavy loads and resist deformation, making it ideal for industrial settings. Another important aspect is its temperature resistance. The mesh performs well in high-temperature environments without losing functionality. Many industries rely on this property for safety and efficiency.

Additionally, stainless steel wire mesh is easy to clean. This feature is significant in food processing and medical applications. However, not all wire mesh is created equal. Some grades may lack the necessary tensile strength. Users must choose wisely based on specific needs. The right choice can enhance performance and reliability in operations.

Standards and Grades of Stainless Steel Used in Wire Mesh Production

Stainless steel wire mesh is widely used in various applications due to its durability and corrosion resistance. The quality of the mesh largely depends on the type of stainless steel used in its production. Multiple grades of stainless steel meet different standards, affecting strength and resistance to environmental factors. The common grades include 304, 316, and 430. Each has unique properties suited for specific applications.

Grade 304, known for its versatility, is often used in food processing and architectural applications. Its resistance to oxidation makes it a popular choice. Conversely, grade 316 offers enhanced resistance to chemicals and salt, vital for marine environments. However, the cost is higher, which can be a limitation for projects with tight budgets.

Grade 430 is magnetic and less resistant to corrosion, making it suitable for indoor applications. While it is more affordable, its limitations in adverse environments can lead to rust over time. It’s crucial to select the proper grade based on the application. This selection process can be challenging, especially when balancing performance and expense. Each project requires thoughtful consideration to ensure the right type of stainless steel wire mesh is chosen.